Sugarcane pulp, often referred to as bagasse, is a fibrous material left after extracting juice from sugarcane stalks. This versatile material has gained attention for its applications in biodegradable and eco-friendly products, particularly in the production of disposable tableware. Understanding the composition of sugarcane pulp is essential to appreciate its role in sustainable living and the manufacturing of green products.

What Is Sugarcane Pulp?

Sugarcane pulp is the byproduct of sugarcane processing, comprising roughly 40-50% cellulose, 25-30% hemicellulose, and 20-30% lignin. This unique composition makes it an excellent material for manufacturing biodegradable products. Its high fiber content provides structural integrity, while the natural sugars and organic compounds allow for easy molding into various shapes without requiring synthetic additives.

Cellulose: The Backbone of Sugarcane Pulp

The primary component of sugarcane pulp is cellulose, a plant-based fiber. It is responsible for giving sugarcane bagasse its strength and durability. Cellulose is a renewable resource, making it an ideal ingredient in biodegradable products. It helps form rigid structures like disposable plates and containers, which can degrade naturally over time, leaving minimal environmental impact.

Hemicellulose: Enhancing Flexibility

Hemicellulose works alongside cellulose to offer flexibility in molded products. It acts as a natural binder, helping maintain the shape of the product while adding some pliability. This property makes sugarcane pulp perfect for items like bowls and cups, which need to retain form while being slightly bendable.

Lignin: The Organic Reinforcer

Lignin, another significant component of sugarcane pulp, acts as a reinforcing agent. It provides additional strength and stiffness to the material, making it capable of withstanding high heat, pressure, and moisture. Lignin also contributes to the natural biodegradability of bagasse, further enhancing its sustainability.

Why Sugarcane Pulp Is Biodegradable

Unlike plastic or Styrofoam, sugarcane pulp is made from natural plant fibers that decompose easily. The absence of synthetic chemicals ensures that the material breaks down in natural environments without harming ecosystems. Depending on environmental conditions, sugarcane pulp products can fully degrade in just 30-90 days, a fraction of the time it takes for plastic to break down.

Sugarcane Pulp in Biodegradable Tableware

At Stuti Exim, we use sugarcane pulp in creating a wide range of biodegradable tableware, such as plates, bowls, and trays. These products are not only eco-friendly but also durable and heat-resistant. This makes them suitable for hot and cold foods, a key advantage over other disposable options.

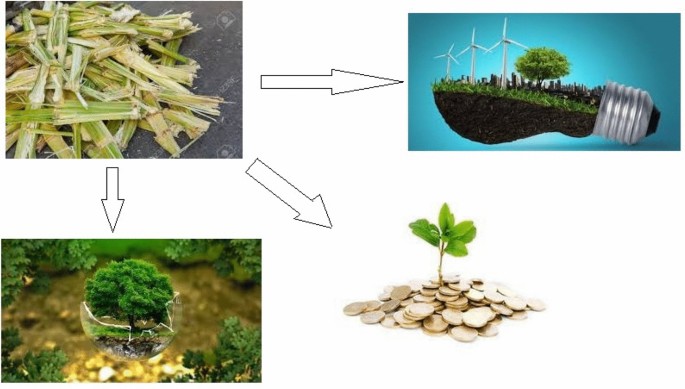

Environmental Benefits of Sugarcane Pulp

- Sustainability: Bagasse is a renewable resource, sourced from the sugarcane industry, which continually replenishes its supply.

- Waste Reduction: Using sugarcane pulp for products repurposes agricultural waste, reducing the need for plastic and decreasing landfill burden.

- Biodegradability: Sugarcane pulp degrades quickly, leaving behind no toxic residue and contributing to healthier ecosystems.

Why Choose Stuti Exim’s Sugarcane Pulp Products?

At Stuti Exim, we are committed to providing high-quality biodegradable products made from sugarcane pulp. Our products not only help reduce plastic waste but also contribute to a circular economy where materials are reused and repurposed for maximum sustainability. Choosing our products is a step towards a greener future.