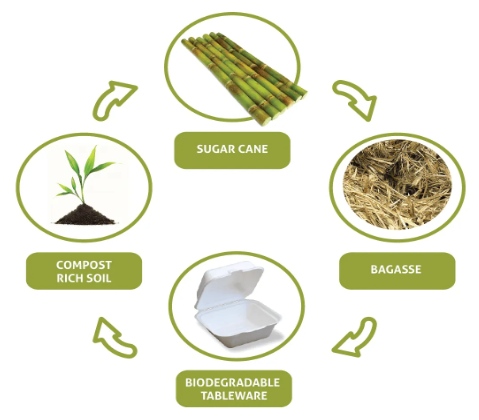

In today’s world, eco-friendly solutions are crucial to reducing our environmental impact. Sugarcane bagasse, a byproduct of the sugar industry, is a fantastic renewable resource that has proven invaluable in creating sustainable, biodegradable tableware. At Stuti Exim, we pride ourselves on offering high-quality, biodegradable tableware crafted from sugarcane bagasse. But how exactly is sugarcane bagasse processed into these eco-friendly products? Let’s explore the sustainable manufacturing journey.

What is Sugarcane Bagasse?

Bagasse is the fibrous material left after the juice has been extracted from sugarcane stalks. Once considered waste, this material is now recognized for its environmental potential as it is compostable and biodegradable. Bagasse processing has become an integral part of the shift towards sustainable, eco-friendly packaging and tableware solutions.

Step-by-Step Process of Turning Sugarcane Bagasse into Tableware

1. Collection and Drying of Bagasse

The journey begins at sugar mills, where sugarcane bagasse is collected after the sugar extraction process. This raw bagasse is full of moisture, so it undergoes a drying phase to reduce the water content. The drying process is essential to ensure that the bagasse fibers are ready for the next step of manufacturing.

2. Pulping the Bagasse

Once dried, the bagasse is processed into a pulp. During pulping, the fibers are mechanically broken down using water and heat. This process creates a smooth, workable pulp that can easily be molded into different shapes and forms.

3. Molding and Shaping

The bagasse pulp is then placed into molds that give it the desired shape. Whether it’s plates, bowls, or clamshells, the flexibility of sugarcane bagasse allows for a wide range of eco-friendly tableware designs. The molds are heated to remove any excess moisture, solidifying the product into its final form.

4. Sterilization and Finishing

To ensure the products are clean, safe, and ready for food contact, the tableware undergoes a sterilization process. This step not only improves the hygiene of the product but also adds strength and durability, making bagasse-based tableware a strong competitor to traditional plastic and paper-based items.

5. Quality Testing

Before packaging, the tableware is subjected to rigorous quality testing. This ensures that the products are sturdy, heat-resistant, and free from defects. At Stuti Exim, we emphasize quality control to meet both domestic and international standards for eco-friendly tableware.

Why Choose Bagasse-Based Tableware?

Using bagasse to make biodegradable tableware is a significant step toward reducing plastic waste. Bagasse-based products have numerous advantages over traditional materials:

- Compostable: Unlike plastic, bagasse products decompose naturally without leaving harmful residues.

- Renewable: Sugarcane is a fast-growing crop, making bagasse a highly renewable resource.

- Heat-Resistant: Bagasse tableware is microwave and oven-safe, offering better performance than paper and plastic products.

The Environmental Impact

At Stuti Exim, we believe that producing tableware from sugarcane bagasse supports the circular economy by transforming agricultural waste into useful products. This not only reduces reliance on single-use plastics but also minimizes environmental pollution and resource depletion.

By choosing biodegradable tableware made from bagasse, businesses and individuals contribute to reducing the global plastic waste problem and promote sustainability in their everyday life.